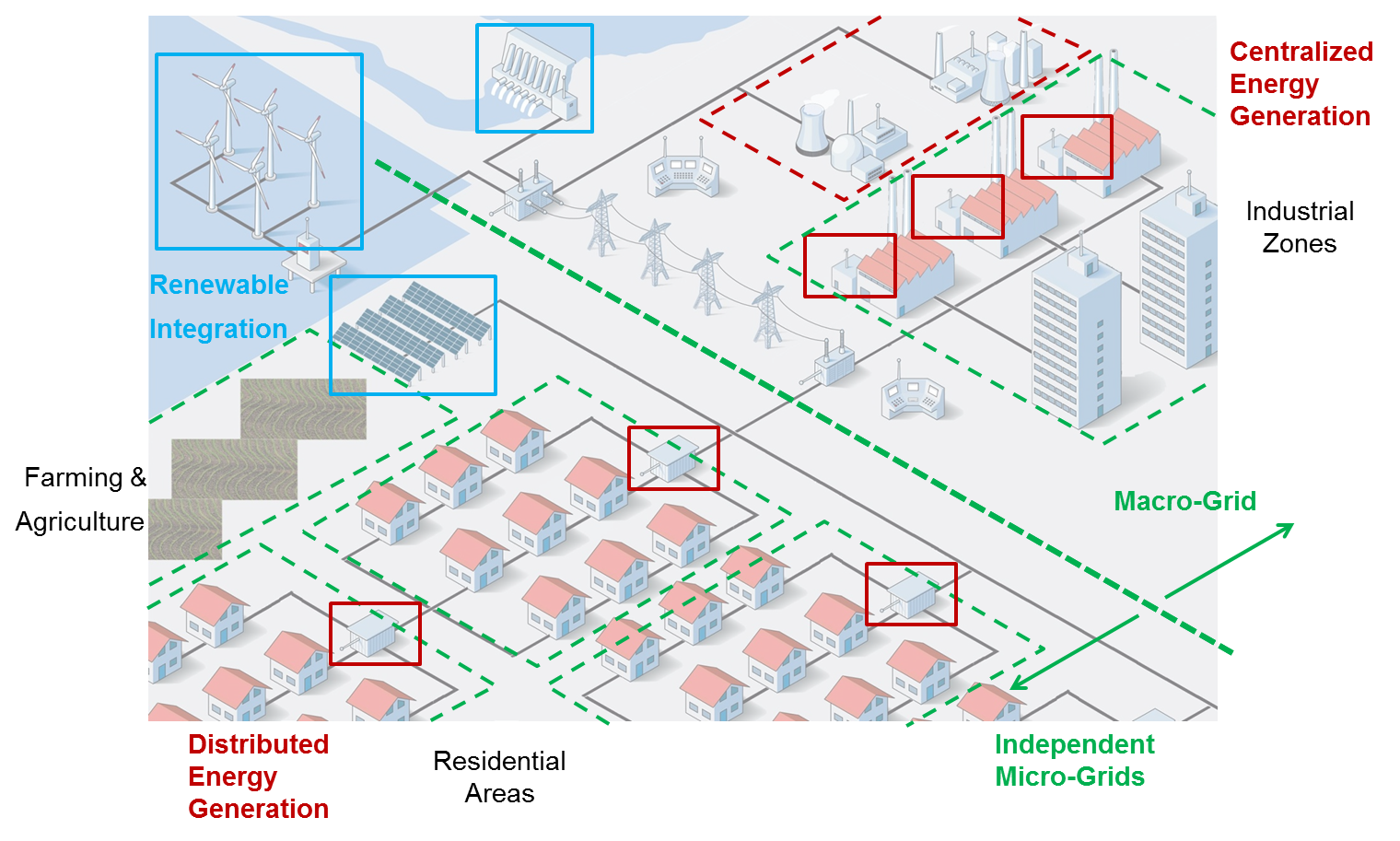

Recent increase in global energy demand augments the usage of natural gas for power generation. This is principally accommodated by the continuing introduction of gas turbine (GT) plant in simple, complex and combined cycle forms. Moreover, the trend towards deregulation of the electricity supply market vastly enhances the emerging ‘‘distributed power generation’’ for efficient distribution of electricity and minimizing losses over long electricity lines. Applying this method, numerous small & efficient gas turbine units will gradually replace few of the large power plants. Therefore, there is a particular interest in the potential of technologies such as micro-turbines, especially in combined heat and power (CHP) applications, where the local main energy consumers become the provider. Consequently, the non-centralized energy infrastructure network becomes more robust, cheaper (gains in efficiency of distribution losses), safer, and also versatile (peak shaving).

Micro-turbines (up to 150kW of electricity) offer a number of advantages compared to other technologies for small-scale power generation such as high power-to-weight ratio, relative size (low terrain footprint), reliability/smaller number of moving parts, lower noise, multi-fuel versatility, lower emissions, and convenient adaptation to combined cycle used for water heating potential. Due to their flexibility (operating in partial or full-load), along with short start-up times, micro gas turbines can be stacked up to create a bank which meets the instantaneous local power demand of their vicinity through-out the day. Distributed power generation with micro gas turbines provides independent clean on-demand energy where you need it, when you need it.

Scientific Objectives

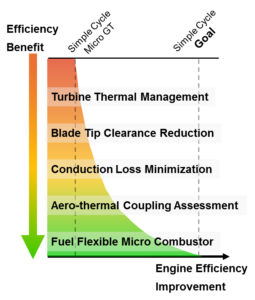

The challenges associated with distributed power generation through micro-gas turbines is an emerging global and national field of study. Therefore, the center fulfills the dual role of creating national expertise in novel turbine component development, and as a major center for size-specific challenges of small air breathing engines; it contributes to bridge the global scientific gap towards wide-spread implementation of this technology. More specifically, the technology center addresses the void of scientific development including:

► Advanced High/Low Pressure Turbine Design for Micro Gas Turbines

- Advanced Turbine Cooling and Thermal Management for Manufacturing Constrained Systems

- Turbine Aerodynamic-Thermal Coupling Assessment

- Minimization of Conduction Losses

- Turbine Tip Clearance Control Methodologies in Dimension-Restrained Environments

► Size Constrained Flexible Fuel Combustor Design Theory and Implementation

► Advanced Micro Gas Turbine Cycle Development and Optimization